With the further implementation of the "14th Five-Year Plan", China is striving to realize the rural revitalization plan. Thus, to promote the high-quality development of renewable energy and realize "carbon peak and carbon neutrality" objectives, "new energy + rural revitalization" is becoming the focus of national and local government works in China, which brings new opportunities for integrated development of photovoltaic projects and rural revitalization, and leads up to the rise of more and more hybrid projects such as photovoltaic agriculture and photovoltaic fishery.

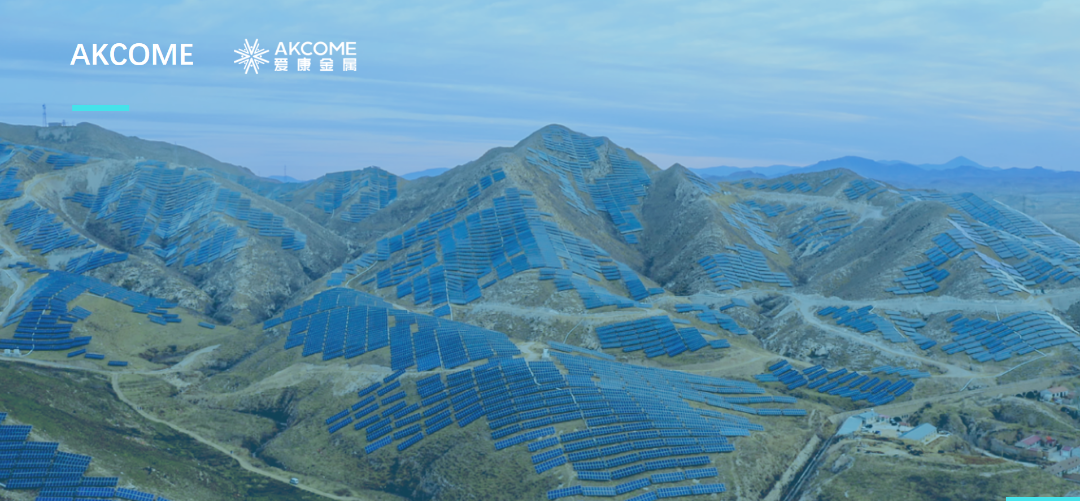

By virtue of special structure, flexible mounts allow for efficient composite land use and applicability in most scenarios, especially projects such as fishery-solar hybrid projects, agricultural-solar hybrid projects, and mountain-based photovoltaic projects.

AKCOME

Flexible and rigid for maximum usability

Compared with traditional PV mounts, flexible ones have many advantages, including lower cost, higher land utilization, faster installation, and higher power generation efficiency. However, due to some technical difficulties, such products have yet to be widely and massively applied. Through continuous innovation, development, upgrade and iteration, AKCOME METALS now is able to provide mature and complete flexible mounting solutions that can not only ensure long-term safe use but also meet the needs of large-span panel laying at a low cost.

All-scenario applications

AKCOME flexible mounting products mainly include two series, i-cross M and i-cross F, which are designed to achieve full coverage of application scenarios including fish ponds, tidal flats, mountains, sewage treatment plants, cross-building structures, and other complex terrain and buildings.

Photo | AKCOME i-cross M

Low cost and high utilization

To meet different needs, AKCOME flexible mounts can adopt either the single-layer prestressed strand structure or double-layer prestressed strand truss structure, with a net span of up to 50m, a headroom of up to 9m, and a total length of about 300m for conventional panel laying arrangement. It is estimated that, compared with traditional mounts, the AKCOME flexible mounting solution requires 40% less pile foundation to achieve the same capacity and 50% less steel to realize the same economical panel laying arrangement, effectively reducing construction costs, and significantly improving land space utilization.

Photo | AKCOME i-cross F

Safe, stable, and durable

In terms of safety and stability, the key to flexible mounting design is to solve the influence of wind vibration and the hidden danger of component tearing. Through wind tunnel test and finite element simulation analysis, including modal analysis of single-layer and double-layer strand structures, wind vibration coefficient analysis, and aerodynamic instability analysis, AKCOME has developed exclusive and innovative wind vibration suppression technology that can effectively improve the wind resistance of its flexible mounts, reduce the risk of component tearing and give the flexible mounts excellent overall structural stability. The load-bearing cable of the mount adopts high-strength and low-relaxation prestressed steel strands, and provides anti-corrosion solutions such as filled epoxy coating together with PE sheath, and high-vanadium cables, achieving excellent corrosion resistance and longer service life.

Real-time monitoring and precise positioning

Stress-induced strand relaxation (especially after high winds) is a major problem for the operation and maintenance of flexible mounts. With the intelligent strand monitoring system that combines common steel strands with optical fiber sensors, AKCOME has realized real-time background monitoring of strand prestress which enabled precise issue identification for more efficient post-maintenance.